Car washing plant "ДЕКО-СМА-4/5" is used for washing of automobiles and trucks.

Spesification

| 1. | Specified capacity | 9 units (5 cars and 4 trucks) per shift. | |

| 2. | Design station mode | Car washing within 8 hours per day | |

| 3. | Recirculated water system: 3.1. Highest concentration of contaminants (suspended solids, petroleum), mg/l: - in waste water influent - in purified water |

Suspended solids 10 000 5 |

Petroleum 5 000 0,1 |

|

| 3.2. Productivity l/sek (m3/hour) | 0,1-0,4 (0,36-1,44) | |

|

| 3.3. Optimum productivity м3/час | 0,45 | |

|

| 3.4. Overall dimensions of cleaner unit, m | (length х width х height): - 3,7 х 1,1 х 3,06 | |

|

| 3.5. Pump (pump model can be changed) | ZXm 1B (PEDROLLO) | |

|

| 3.6. Capacity of the electric motor of the pump, kW | 0,5 | |

|

| 3.7. Pump supply voltage, V | 220 -240 | |

| 4. | Mud trap, dimensions, m. | ( length х width х height): - 4,0 х 0,8 х 1,5 | |

| 5. | Weight of the plant (not more) т.: - dry (without mud trap) - in fined state (without mud trap) |

2,2 5,5 | |

| 6. | Weight of mud trap, t.: | 0,53 | |

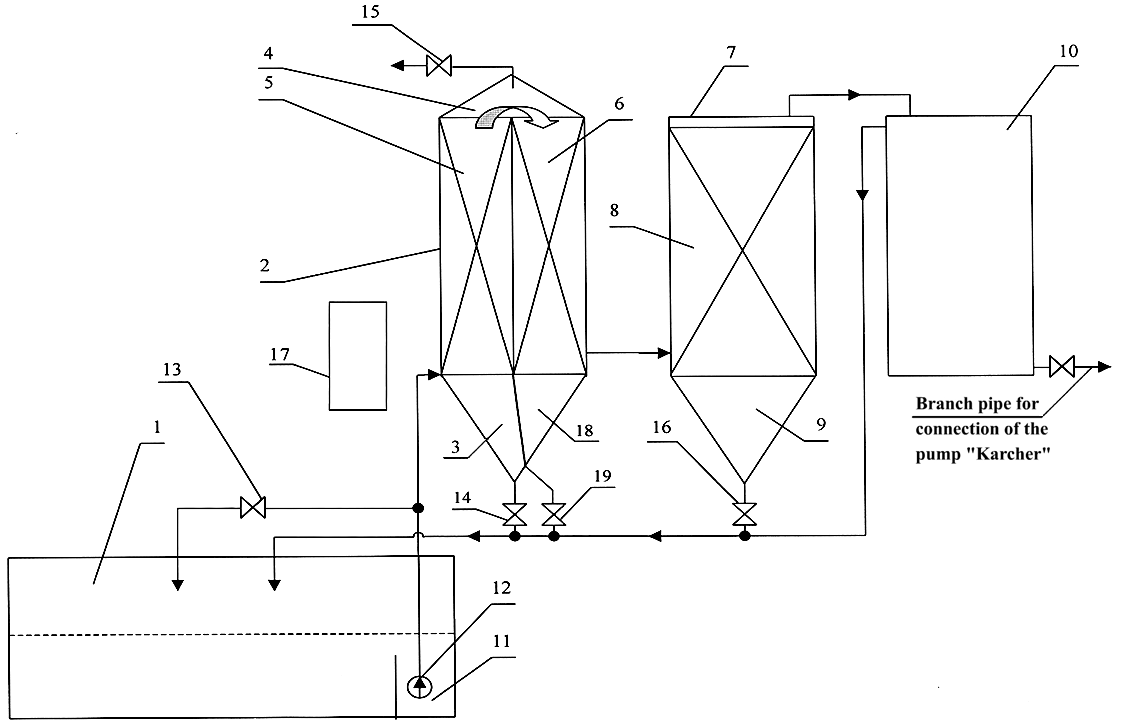

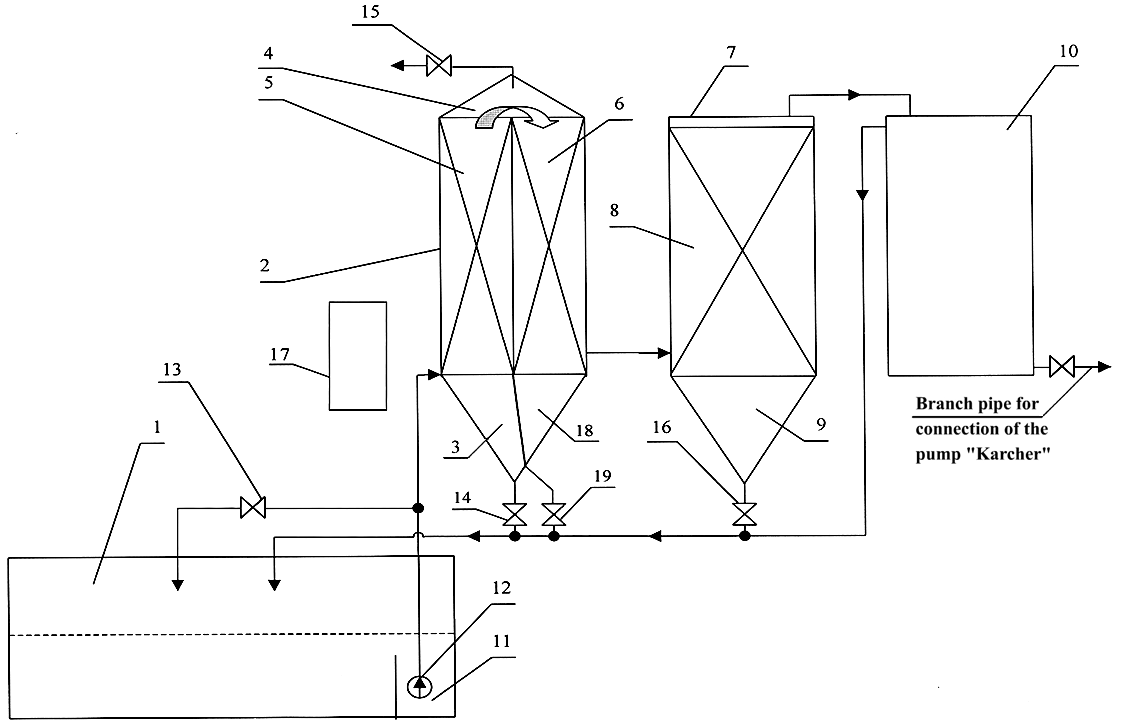

The basic scheme of turnaround water supply (Fig.1)

Explication

| 1 - receiving mud settler pan | 11 - reseption well, |

| 2 - body | 12 - pump |

| 3 - intermediate mud-settling pit | 13 - regulating cock |

| 4 - chamber | 14 - sludge bleeding tap |

| 5 - silt-settling tank | 15 - tap of periodic removal of the trapped mineral oil |

| 6 - filter | 16 - sludge bleeding tap |

| 7 - body | 17 - oil storage tank |

| 8 - sorption chamber | 18 - intermediate mud-settling pit |

| 9 - intermediate mud-settling pit | 19 - sludge bleeding tap |

| 10 - clear water tank |

|

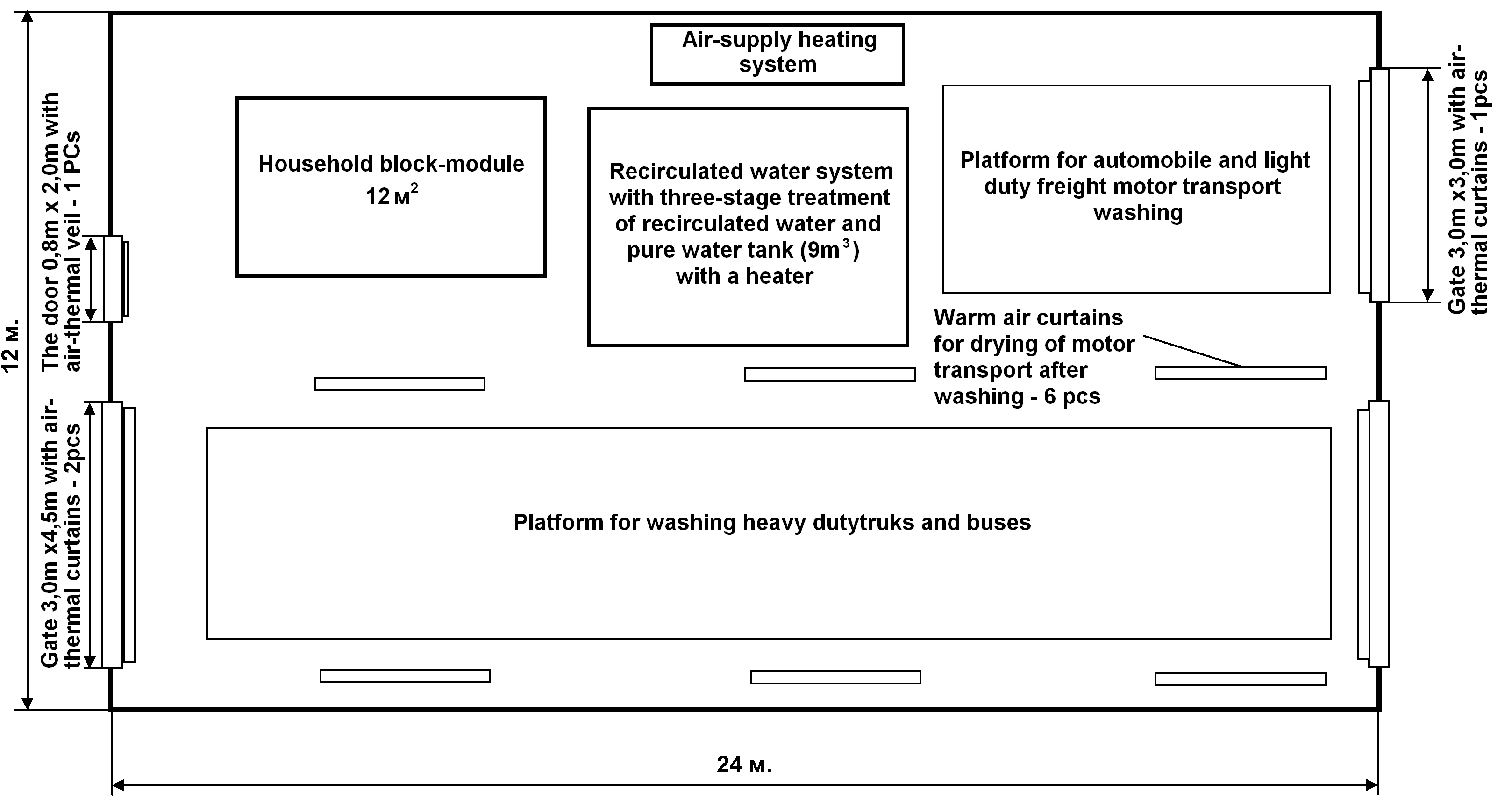

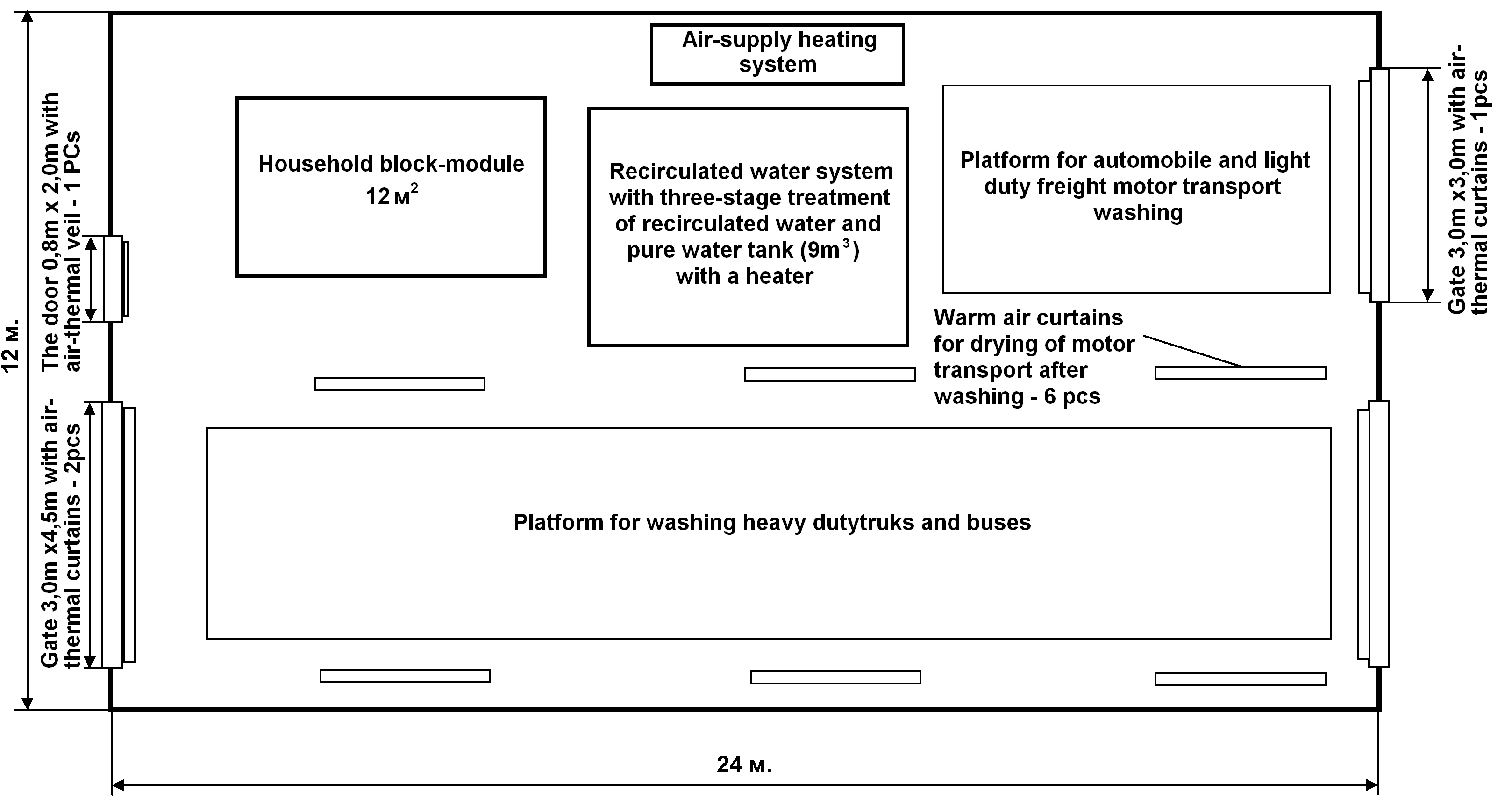

The general structure of car washing plant

"ДЕКО-СМА-4/5"

The station building is delivered according to a climatic belt, up to settlement temperature-550С. Also it is equipped by built in on mark +2,2m the household block module (12m2) with a bathroom, a washstand with a watering can, and a household premise for attendants. Under the block module it is mounted an automatic sewerage pump station with a tank and the pump.

The station building has:

- The system of water heating which provides a maintenance of necessary temperature indoors in a cold season and energized from the available general heating system. The structure of system of water heating includes registers, connecting pipelines, stop valves;

- The system of illumination, which provides the demanded level of light exposure in a building and on workplaces. It includes ceiling and local fixtures, switches and so forth of corresponding (IP 44) executions.

- The exhaust ventilation, carrying out the removal of a superfluous moisture from internal volume of a building of station and is made as two axial fans, established in the top part of the face walls of a building;

- The forced ventilation providing of supply of fresh air into a building of station, which compensates the volume of air deleted by exhaust ventilation. If necessary it is carried out the heating of the incoming air by a heater.

- The warm air curtain of horizontal-shell-type located over the gate opening, with electroheating of a locking stream of air. In a cold season the warm air curtains provide the effective energy saving, keeping a heat indoors, and in warm season they interfere with hit of insects into a building. Switching on and off of warm air curtains is carried out automatically accordingly at opening and closing of a gate. The warm air curtains for drying of motor transport are located in a working area of car washing plant. Switching of warm air curtains is manual.

The recirculated water system is carries out the effective treatment of discharged water from mineral oil and mechanical impurity, and heating of the treated water up to 600С.

Process of car washing is carried out by recirculated water system by two high-pressure apparatuses «Karcher».

The power-supply system of a station provides energization of all energy-consuming equipment and power control.

The power-supply system of a station consists of:

- input distribution system;

- power cabinet of heating system a and ventilation system;

- light system panel;

- pump and high-pressure apparatuses «Karcher» control panel;

- Recirculated water system;

- Cables of a distribution and group network.

The basic features of work of car washing plant "ДЕКО-СМА-4/5" are:

- All the works execute in the closed and heated premise;

- Using of high-pressure apparatuses «Karcher»;

- Using of recirculated water system, that makes possible to reuse the water after washing and also to realize

its and treatment and heating before use.

Work of recirculated water system is carried out as follows:

The polluted water from car-washing facility flows into the receiving mud settler pan 1 where it is preliminary desilted (sludge settles, and the particles of mineral oil emerge on a surface, forming a floating film).

As a water level in the receiving mud settler pan 1 increase, the operating float activate the pump 12 which submits water to treatment through the pressure head pipeline. Setting of the design water discharge on treatment unit is carried out due to regulation of the charge in a recirculating line by regulating cock 13. From the pressure head pipeline the polluted water flows into the silt-settling tank 5 where the caught suspended solids settle in intermediate mud-settling pit 3 (I-st stage of treatment), and parts of mineral oil, emerging, collect as a film on internal surfaces of pipes, and (due to a difference between relative densities of water and mineral oil) move upwards. Further they come off a film in a form of larger drops and are taken out by the basic stream to the chamber 4 where they collect in the top part in the form of a floating film. After silt-settling tank 5, partially treated water, flows into the filter 6, where the subsequent treatment is carried out.

Minor particles of mineral oil which have not integrated in silt-settling tank 5, moving between floating granules, touch them and pass as a film to their surface. As a thickness of a film increase, mineral oil pass (due to a difference of relative densities) in a film of above granules and, finally, emerge in the form of large drops in a floating film of the chamber 4.

Simultaneously to integration of fine drops of mineral oil it takes place an integration of fine fractions of the suspended solids which settle in the intermediate mud-settling pit 18 (II-nd stage of treatment).

Final deep water treating is carried out in sorption chamber 8, whence water is taken away to the clear water tank 10 where it is heated. Selection of the heated water for the work of high pressure apparatuses of a type «Karcher» is carried out from the clear water tank 10.

Designation when order (example): Car washing plant "ДЕКО-СМА-4/5".

Photo gallery

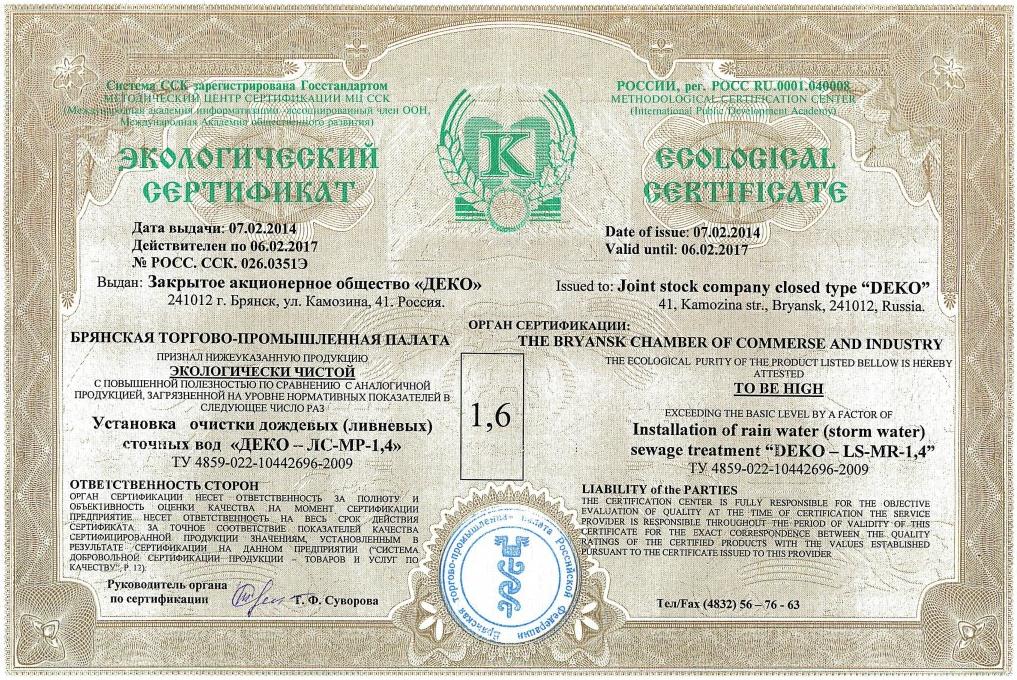

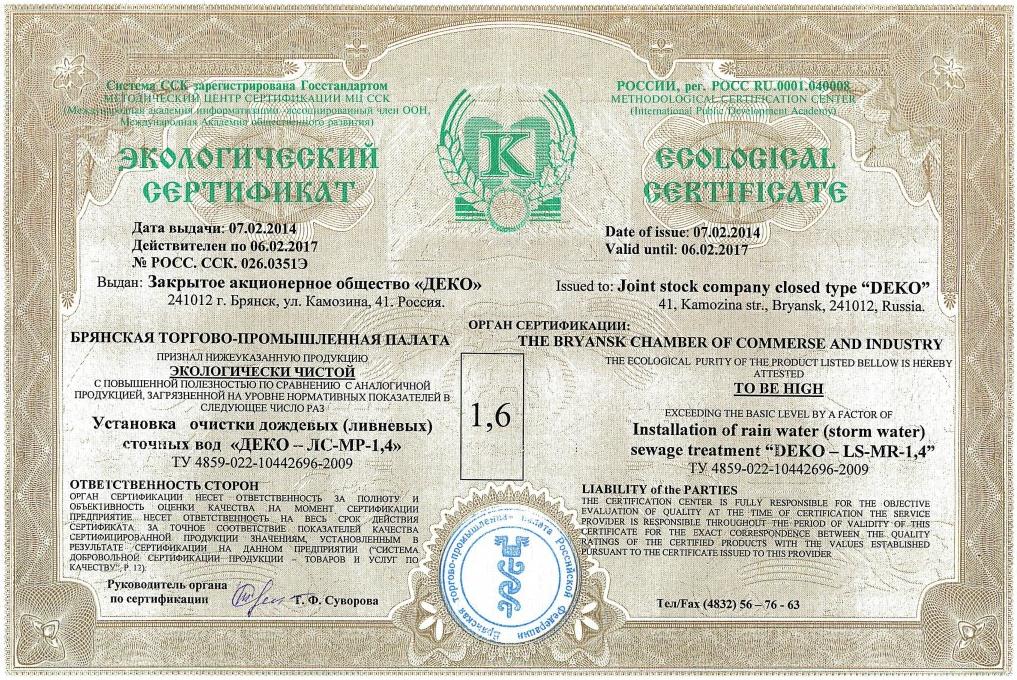

Ecological certificate

Certificate of conformance

Теl./fax: (4832) 56-59-38

(4832) 52-19-33

(4832) 57-76-04

Company "ДЕКО", Brjansk

Wastewater treatment

and gas emissions

- Eng

- Rus