A Biological Sewage Treatment Plant ("СБОСВ") is a single building equipped with heating, lighting, vacuum ventilation and extraction systems.

The building with all the technological equipment inside is put up on a single monolithic reinforced concrete platform. The plant can contain one or several (the number is potentially unlimited) technological lines of sewage treatment and sanitation depending on the required capacity and customer’s wishes. The capacity of one technological line can be 30, 60, 100 or 200 cubic meters of wastewater per day. For the given figures all the technological equipment is supplied in the form of maximally prefabricated blocks, which considerably reduces the labor intensity and duration of installation work.

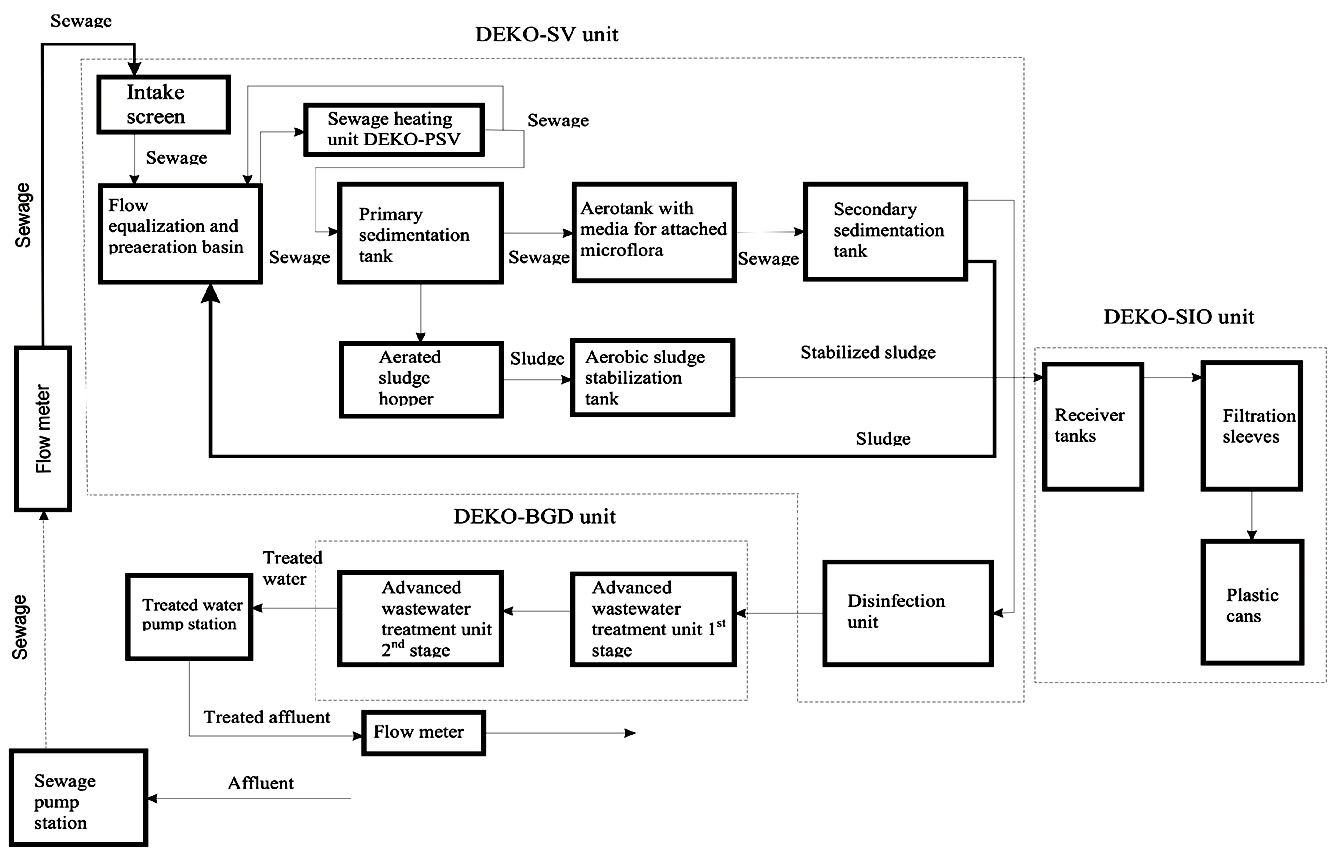

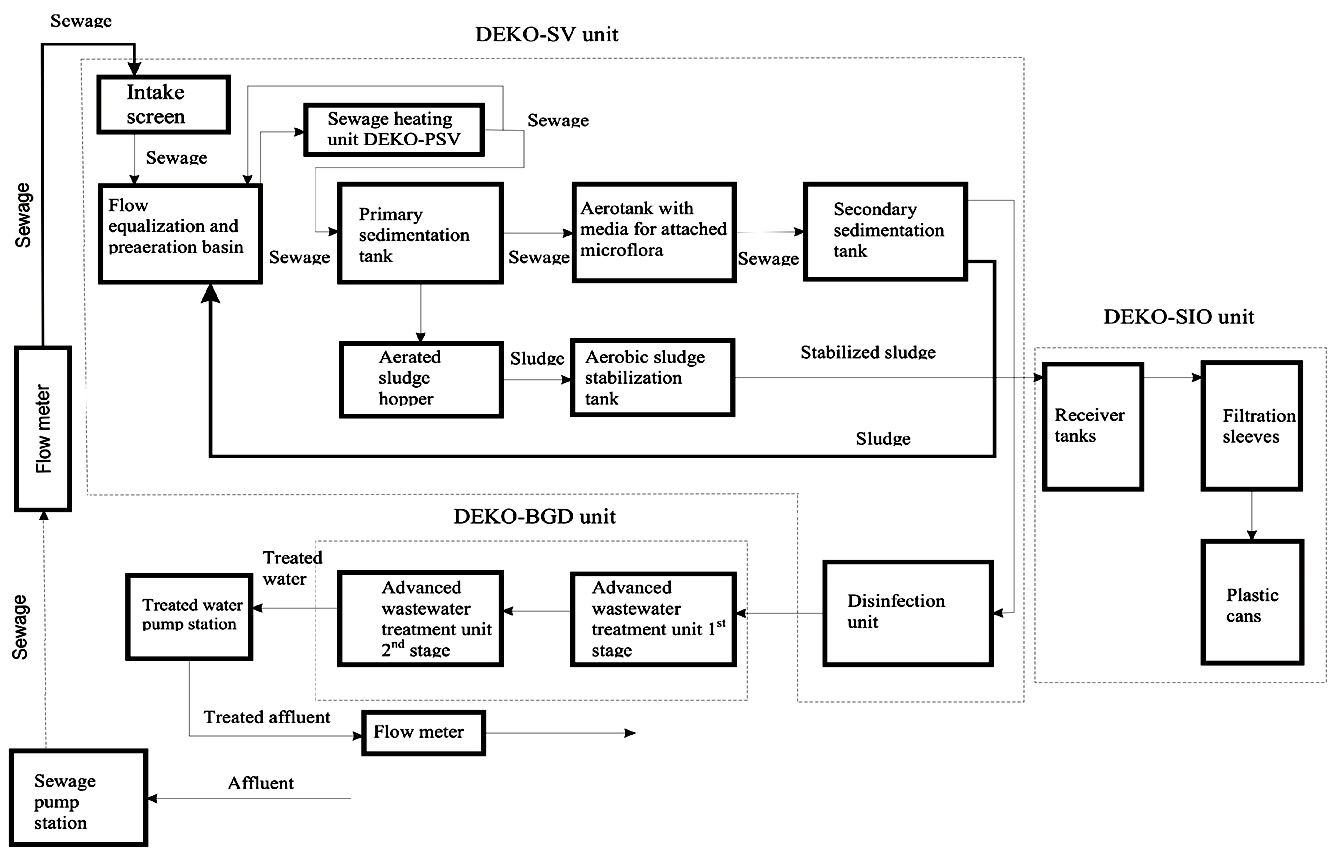

The operating principle and structure of the technological line of sewage treatment and sanitation are the following.

The rate of the sewage water flow coming from a sewage pump station to the "СБОСВ" is continually registered with a non-invasive flow meter (see the block diagram).

Then the sewage passes through the heating unit, where the optimum temperature is reached, and goes to the intake screen of the "ДЕКО-СВ" unit, through which it moves into the flow equalization and preaeration basin. The flow equalization and preaeration basin is equipped with aeration and sewage recirculation systems and self-regenerating media for attached microflora.

From the flow equalization and preaeration basin the sewage flows to the primary thin-layer sedimentation tank (at a fixed rate of flow per day). The collected suspended matter is then driven to the aerated hopper, while the clarified sewage goes to the first stage of the aerotank. All the stages of the aerotank are equipped with aeration systems and self-regenerating media for attached microflora. The concentration of dissolved contaminants will be smaller at every next stage, and this determines every stage having a unique set of microorganisms according to the composition and concentration of contaminants. After passing all the stages of the aerotank the dissolved contaminants are completely removed from the sewage.

From the last stage of the aerotank the sewage passes to the secondary thin-layer sedimentation tank. The trapped suspended matter, including biological floc, is regularly driven to the flow equalization and preaeration basin, while the treated water goes to the disinfection unit fitted with ultraviolet lamps. From the disinfection unit the water passes through the two stages of the advanced wastewater treatment unit ("ДЕКО-БГД") to the treated water pump station which takes it away from the "СБОСВ". Before the treated affluent leaves the plant, its flow is checked with a non-invasive flow meter.

All the collected sludge is driven away from the technological line of sewage treatment through the primary thin-layer sedimentation tank and the aerated hopper. From the aerated hopper the sludge is regularly and automatically driven first to the aerobic sludge stabilization tank and then to the receiver tanks of the "ДЕКО-СИО" unit(s).

From the receiver tanks of the "ДЕКО-СИО" unit(s) the sludge is manually distributed by the operating personnel into the filtration sleeves. The disinfected and sterile sludge with humidity of 5-10 %, left in the filtration sleeves after the previous cycle of sludge treatment, is manually unloaded in the plastic cans and then packed into hermetically-sealed plastic bags.

Block-diagram of the technological line of sewage treatment and sanitation

Operation and Maintenance

Maintenance of the equipment of the plant is performed in accordance with the technological regulations issued by specialized organizations which carried out the start-up and commissioning of the plant.

The operation of the plant is automated. All the energy-consuming continuously working equipment has a 100% operating reserve. In case the main equipment stops functioning, the reserve equipment begins to function automatically with a signal sent to the control unit to inform about switching.

All the energy-consuming intermittently working equipment has a 100% stock reserve.

The attending personnel’s involvement in operating the plant is primarily necessary for regular (once a shift) removal of the collected trash from the intake screen and visual control of all the aeration systems and the UV lamps of the disinfection unit. Besides, every 5-7 days (the exact period is determined individually by the commissioning contractor) the operating personnel are to unload and refill manually the "ДЕКО-СИО" unit(s).

Key Advantages over Known Counterparts

The key advantages of the "СБОСВ" over the known counterparts (according to available information) are the following:

1. The plants do not require sludge drying beds whereas they completely accomplish the task of sludge

disinfection and utilization.

2. The plant operation does not require chemical agents.

3. The media for attached micro flora do not need periodic regeneration. The "ДЕКО-СВ" unit uses self-

regenerating media for attached micro flora.

4. The plants are equally effective in clarifying usual household sewage and highly diluted sewage.

5. The plants can be equally effective in sewage treatment at full or 5% capacity.

6. The design of the plant creates maximally comfortable conditions for operating and repair personnel.

7. All the technological processes can be easily controlled visually.

8. The disinfection blocks do not require periodical switching and cleaning.

"СБОСВ-600" on the "СОГ-4"

on the Compressor station Jamburgskaja

Mounting of equipment.

"СБОСВ-100" on the

Compressor station Novourengojskaya.

View of the station.

"СБОСВ-200" on the

Compressor station Pangodinskaya.

View of the station.

"СБОСВ-800" on the

Compressor station Sos'vinskaya.

View of the station.

Installation "ДЕКО-СВ-30" and

"ДЕКО-БГД-30" after mounting

Installation "ДЕКО-СВ-30"

at work.

"СБОСВ-100". Control panel and consumer unit-Boxing.

Installation "ДЕКО-СИО".

Shipment by road.

Installation "ДЕКО-СИО".

Mounting

Control panel "СБОСВ-800".

Installation "СБОСВ-800"

Installation "СБОСВ-800"

Adjustment of electrical equipment.

Control panels "СБОСВ-800".

"СБОСВ-100". Instruction of the operating personnel.

Station "СБОСВ".

Equipped interior.

Certificate of conformance

"ДЕКО-СИО"

Ecological certificate

Certificate of conformance

"ДЕКО-СВ"

Теl./fax: (4832) 56-59-38

(4832) 52-19-33

(4832) 57-76-04

Company "ДЕКО", Brjansk

Wastewater treatment

and gas emissions

- Eng

- Rus