Biological treatment plant ДЕКО-СВ with a productivity

rate of 10 m3/day.

ТУ 4859-020-10442696-2009

Specifications

| № | Parameters | Points of measure | ДЕКО-СВ-1М | ДЕКО-СВ-5М |

| 1. | Capacity | m3 /day | 1,0-3,0 | 5,0-7,5 |

| 2. | Dimensions, B´L´H (without access hatches) | m | 3,100 х 6,715 х 3,415 | 3,100 х 8,265 х 3,415 |

| 3. | Weight (dry) | t | 10,80 | 11,97 |

| 4. | Operating weight (with water) | t | ~ 25,00 | ~ 33,00 |

| 5. | Rated output power | kW | 9,245 | 9,245 |

| 6. | Махimum electric power consumption | kW/hour | 7,91 | 7,91 |

| 7.

| The main parameters of ultraviolet sources: - wave-length - radiation intensity, applied to the water |

оА мW-с/sm2 |

2537 not more than 28 |

2537 not more than 28 |

| 8. | Coefficient of reflection of ultraviolet reflectors |

| 0,6-0,9 | 0,6-0,9 |

| 9. | Time of water exposure | sek. | 15-30 | 15-25 |

| 10. | Mark of a frame bottom of a plant | m. | (-4,2), (-4,7), (-5,2), (-5,7), (-6,2) | |

| 11. | Distance (cable length) from the plant to the control board | m. | Up to 450 | |

Technological parameters of work of biological treatment plant ДЕКО-СВ

| № | Parameters | Point of measure | before treatment (benchmarks) | after treatment |

| 1. | Coliforming bacteria | CFU/100ml | 106-108 | 50-100 |

| 2. | Coliphages | PFU /100ml | 103-104 | 50-100 |

| 3. | Thermotolerant coliforming bacteria | CFU /100ml | 103-106 | 50-100 |

| 4. | Fecal streptococcus | CFU /100ml | 103-104 | 5-10 |

| 5. | Pathogenic microorganisms |

|

| 0 |

Мicrobiological parameters of work of biological treatment plant ДЕКО-СВ

| № | Parameters | Point of measure | before treatment (benchmarks) | after treatment |

| 1. | Suspended solids (SS) | mg/l | up to 275 | 3-5 |

| 2. | BOD5 | mg/l | up to 300 | 3-5 |

| 3. | Temperature | 0С | 18-25 | 18-25 |

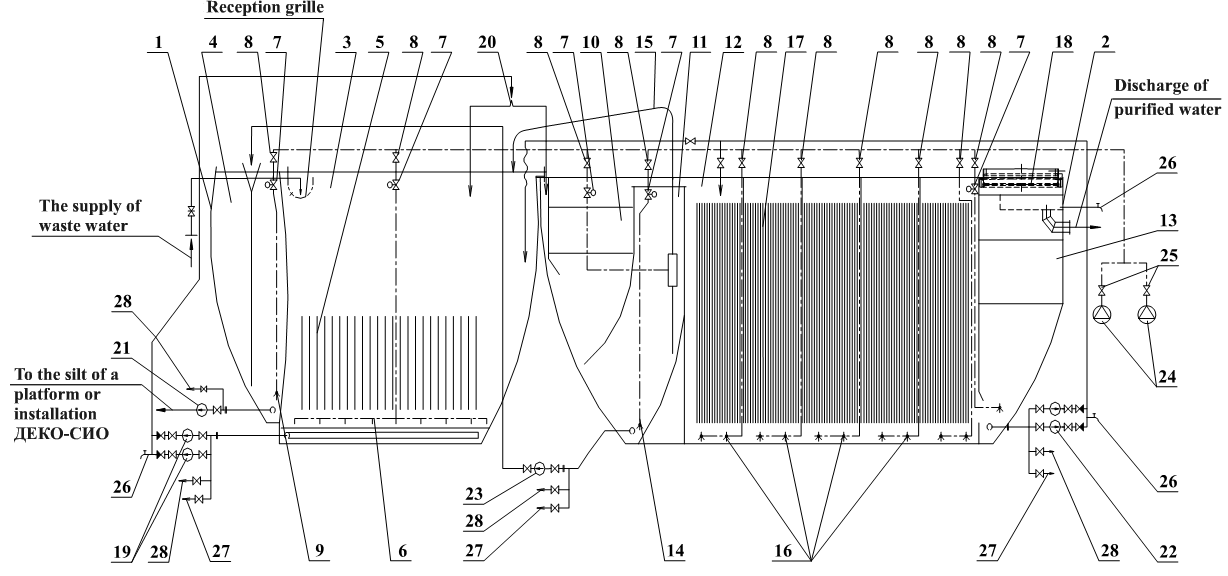

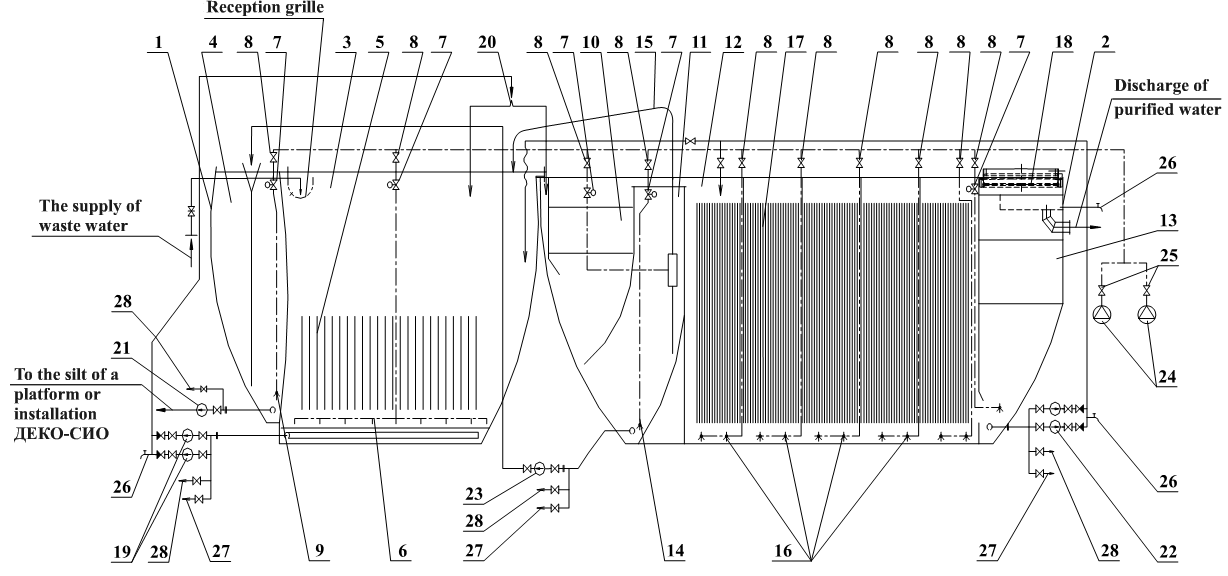

Principle process diagram of biological treatment plant ДЕКО-СВ

Explication

| 1. | Casing; | 18. | Overflow pipe; |

| 2. | Septic tank; | 19. | Adsorption charge; |

| 3. | Technical chember; | 20. | Bactericidal disinfection unit; |

| 4. | Aeration tank; | 21. | Clean water to outfall pump; |

| 5. | Unit of advanced waste water treatment; | 22. | Return valve; |

| 6. | Aerator; | 23. | Valve; |

| 7. | Pressurized air supply and guidance systems; | 24. | Valve bypass; |

| 8. | Air blowers; | 25. | Emergency drain valve; |

| 9. | Thin-layer silt-settling tank; | 26. | Shaft; |

| 10. | Air-lift system; | 27. | Shaft; |

| 11. | Sewage supply system; | 28. | Airshaft; |

| 12. | Sludge return system; | 29. | Airshaft; |

| 13. | Rinsate and drainage water disposal system; | 30. | Fan; |

| 14. | Sampler; | 31. | General electrical resistance heater; |

| 15. | Electromagnetic valve; | 32. | Air-heating unit; |

| 16. | Waste water supply header; | 33. | Supply grill; |

| 17. | Bypass collector; | 34. | Drainage pump. |

Operating mode of installation ДЕКО-СВ-1М is automatic continuous.

Sewage pass consistently mechanical clearing in a septic tank 2 and full biological clearing in the aeration tank 4. The further processing of sewage treatment is carried out in the unit of advanced waste water treatment 5. The sludge formed during the sewage treatment, gather in the chamber of a septic tank 2 and exposed to anaerobic stabilisation. Efficiency of removal of the basic pollution makes 95-99 %. The salt structure of cleared water is actually doesn’t changes.

Work of biological treatment plant ДЕКО-СВ-1М is carried out as follows.

Sewage come in a septic tank 2 where there is a sedimentation of the suspended solids with simultaneous accumulation and anaerobic digestion of the sludge. The septic tank volume is determined in accordance with the requirements СНиП 2 2.04.03-85 item 6.79.

Periodicity of an unloading of a sludge depends on water contamination level and a quantity of the sewage which have passed through the plant during the design-basis time interval. In case of clearing of every day the demanded periodicity of removal of a sludge makes 1-2 times a year. Digested sludge leaves by sewage cesspool tank truck through a hatch cover on casing.

After the septic tank 2 sewage through the sewage supply system 11 arrive to the aerotank 4 (unit of biological treatment) where the organic pollution sorbed and simultaneously are oxidized by microorganisms, attached on the special carrier (bacteria bed) located in volume of unit of biological treatment. For maintenance of microorganisms vital processes aerotank it is constantly aerated by air through аerators 6, located below the bacteria bed. Air for aeration moves on pipelines of pressurized air supply and guidance systems 7 from compressors 8 (air blowers). The quantity of air submitted for aeration into aerotank 4, is calculated according to requirements СНиП 2.04.03-85 item 6.157 as for system with medium bubbling aerations.

Having passed through aerotank 4 sewage come into thin-layer silt-settling tank 9 where there is an entrapping of the suspended solids, including the fulfilled biofilm. Periodically (each 1-1,5 hours) there is a short-term automatic switching on of air-lift 10.

Air-lift 10 carries out the pumpage of suspended solids, entapped in silt-settling tank. For the work of air-lift 10 it is used the air from pressurized air supply and guidance systems. This scheme of work of biological treatment plant ДЕКО-CВ-1М provides storage and processing of sludge in one capacity that simplifies their subsequent fence and increases efficiency of upholding of water in the septic chamber as the superfluous biofilm carries out a role of reagent, sorbing on the surface a part of the pollution containing in initial water.

After thin-layer silt-settling tank 9 water comes into the unit of advanced waste water treatment 5, and, after, to the block of bactericidal disinfecting 20.

The cleared and disinfected water is taken away to the collector, and, after, it is pumped by pump 21 onto local terrain or to a reservoir.

Emergency dumping and washing of cases of aerotank systems 4 and unit of advanced waste water treatment 5 is carried out at open valves 25 through drain branch pipes in drainage capacity at the bottom of the case 1 in technological chamber, whence by the pump 34 through the rinsate and drainage water disposal system 13 it is pumped into a septic tank 2.

Shipment of sewage treatment plant

ДЕКО-СВ-1М by rail.

Designation when order (example):

“Sewage treatment plant ДЕКО-СВ-1М, depth mark of a frame bottom of a plant (-5,7) m., cable length from the plant to the control board – 400 m.”

Ecological certificate

Certificate of conformance

Теl./fax: (4832) 56-59-38

(4832) 52-19-33

(4832) 57-76-04

Company "ДЕКО", Brjansk

Wastewater treatment

and gas emissions

- Eng

- Rus