Sewage treatment plant for recirculated water system “ДЕКО-ЛС”

ТУ 4859-023-10442696-2009

Specifications

| № п/п | Parameters | Point of measure | Value |

| 1. | Maximum performance | l/sek. (m3/hour) | 0,33 (1,2) |

| 2. | Overall dimension of cleaner unit with frame (not more) LхBхH | m. | 2,510 х 1,260 х 2,670 |

| 3. | Accumulator unit for purified water (9m3 ) Overall dimensions with frame (not more) LхBхH | m. | 3,050 х 2,370 х 3,305 |

| 4. | Mud trap. Overall dimensions with frame (not more) LхBхH | m. | 5,050 х 1,030 х 1,150 |

| 5. | Pump motor capacity | kW | 0,6 |

| 6. | Power voltage | V | 220-240 |

| 7. | Weight of sewage treatment plant (not more) - dry (without mud trap) - in maximum fined state (without mud trap) - mud trap weight |

t. t. t. |

3,41 28,0 0,685 |

Performance goals

| № | Contaminations | Point of measure | Before treatment | After treatment |

| 1. | Suspended solids (SS) | mg/l | no limit | less than 5 mg/l |

| 2. | Oils | mg/l | no limit | less than 0,05 mg/l |

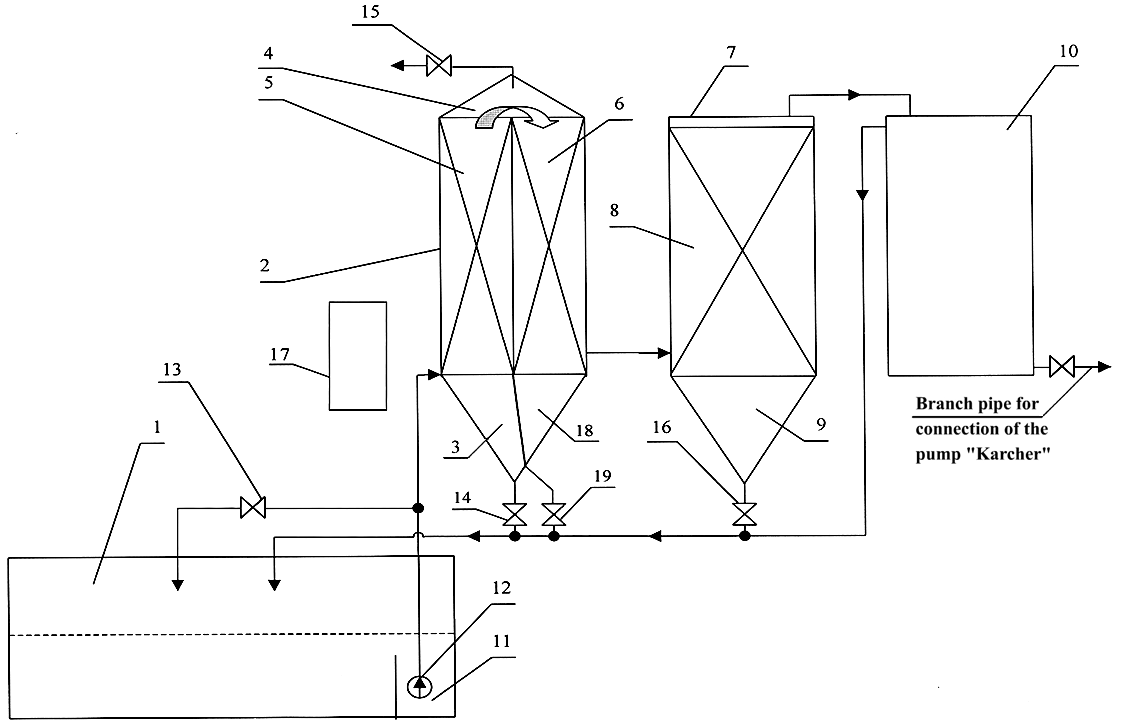

Principal Process Diagram

Sewage treatment plant for recirculated water system "ДЕКО-ЛС-1,2" is used for treatment of waste water from suspended solids and oils in recirculated water system of different function, including for car-washing facilities.

Sewage treatment plant "ДЕКО-ЛС-1,2" provides treatment of the specified sewage to the indicators corresponding to requirements ОНТП-01-91 "РОСАВТОТРАНС" (the appendix 5, table 3) for an external washing of cars and buses.

Explication

| 1 - receiving mud settler pan | 11 - reseption well, |

| 2 - body | 12 - pump |

| 3 - intermediate mud-settling pit | 13 - regulating cock |

| 4 - chamber | 14 - sludge bleeding tap |

| 5 - silt-settling tank | 15 - tap of periodic removal of the trapped mineral oil |

| 6 - filter | 16 - sludge bleeding tap |

| 7 - body | 17 - oil storage tank |

| 8 - sorption chamber | 18 - intermediate mud-se ttling pit |

| 9 - intermediate mud-settling pit | 19 - sludge bleeding tap |

| 10 - clear water tank |

|

Work of recirculated water system is carried out as follows:

The polluted water from car-washing facility flows into the receiving mud settler pan 1 where it is preliminary desilted (sludge settles, and the particles of mineral oil emerge on a surface, forming a floating film).

As a water level in the receiving mud settler pan 1 increase, the operating float activate the pump 12 which submits water to treatment through the pressure head pipeline. Setting of the design water discharge on treatment unit is carried out due to regulation of the charge in a recirculating line by regulating cock 13. From the pressure head pipeline the polluted water flows into the silt-settling tank 5 where the caught suspended solids settle in intermediate mud-settling pit 3 (I-st stage of treatment), and parts of mineral oil, emerging, collect as a film on internal surfaces of pipes, and (due to a difference between relative densities of water and mineral oil) move upwards. Further they come off a film in a form of larger drops and are taken out by the basic stream to the chamber 4 where they collect in the top part in the form of a floating film. After silt-settling tank 5, partially treated water, flows into the filter 6, where the subsequent treatment is carried out.

Minor particles of mineral oil which have not integrated in silt-settling tank 5, moving between floating granules, touch them and pass as a film to their surface. As a thickness of a film increase, mineral oil pass (due to a difference of relative densities) in a film of above granules and, finally, emerge in the form of large drops in a floating film of the chamber 4.

Simultaneously to integration of fine drops of mineral oil it takes place an integration of fine fractions of the suspended solids which settle in the intermediate mud-settling pit 18 (II-nd stage of treatment).

Final deep water treating is carried out in sorption chamber 8, whence water is taken away to the clear water tank 10 where it is heated. Selection of the heated water for the work of high pressure apparatuses of a type "Karcher" is carried out from the clear water tank 10.

Ready-mounted sewage treatment plant for treatment of waste water from suspended

solids and oils "ДЕКО-ЛС-1,2".

Designation when order (example):

"Sewage treatment plant for treatment of waste water from suspended solids and oils "ДЕКО-ЛС-1,2", ТУ 4859-023-10442696-2009"

Ecological certificate

Certificate of conformance

Теl./fax: (4832) 56-59-38

(4832) 52-19-33

(4832) 57-76-04

Company "ДЕКО", Brjansk

Wastewater treatment

and gas emissions

- Eng

- Rus