Biological treatment plant ДЕКО-СВ

with a productivity rate of 30 - 200 m3/day.

ТУ 4859-019-10442696-2009

Biological treatment plants ДЕКО-СВ are used for integrated waste water treatment.

Biological treatment plants ДЕКО-СВ (with advanced treatment units ДЕКО-БГД) provide clearing of the specified sewage up to the indexes that satisfy the requirements of current environmental regulations, that allows to discharge of sewage waters in any reservoir, in drainage systems, onto local terrain, etc.

TECHNOLOGICAL AND MICROBIOLOGICAL PARAMETERS

Technological parameters of work of biological treatment plant ДЕКО-СВ

(with advanced treatment units ДЕКО-БГД) Таb.1

| № | Parameters | Point of measure | Before treatment | After advanced treatment |

| 1. | Suspended solids (SS) | mg/l | до 200 | 3 – 5 |

| 2. | BOD5 | mg/l | до 200 | 3 – 5 |

| 3. | COD | mg/l | до 500 | 10-20 |

| 4. | рН |

| 6,5-8,5 | 6,5-8,5 |

| 5. | Colour | color degree | no applicable regulations | 1-20 |

| 6. | Temperature | оС | 16-23 | 18-25 |

| 7. | Petroleum | mg/l | До 1,0 | 0,04-0,5 |

| 8. | Chlorides | mg/l | 5-300 | 4-270 |

| 9. | Synthetic Surfactants | mg/l | До 5,0 | 0.5-0,8 |

| 10. | Ammonium nitrogen | mg/l | 45 | 0,1 – 3,0 |

| 11. | Nitrite nitrogen (NO2-N) | mg/l | 0,0-0,5 | 0,01 – 0,1 |

| 12. | Nitrate nitrogen (NO3-N) | mg/l | 0,0-0,5 | 7 – 9 |

| 13. | Phosphates | mg/l | до 10,0 | 0,1 – 1,0 |

| 14. | Acceptable interruption of water supply | — | Not allowed | |

Мicrobiological parameters of work of biological treatment plant ДЕКО-СВ

(with advanced treatment units ДЕКО-БГД) Таb. 2

| № | Parameters | Point of measure | before treatment (benchmarks) | after advanced treatment |

| 1. | Coliforming bacteria | CFU /100ml | 106-108 | 50-100 |

| 2. | Coliphages | PFU /100ml | 103-104 | 50-100 |

| 3. | Thermotolerant coliforming bacteria |

CFU /100ml |

103-106 |

50-100 |

| 4. | Fecal streptococcus | CFU /100ml | 103-104 | 5-10 |

| 5. | Pathogenic microorganisms |

|

| 0 |

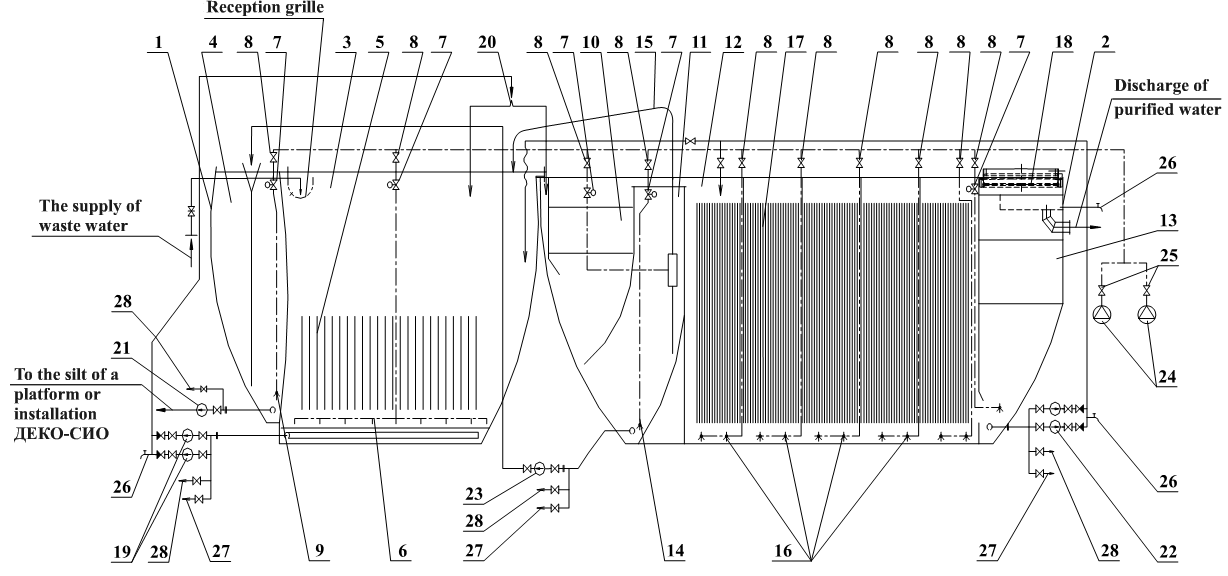

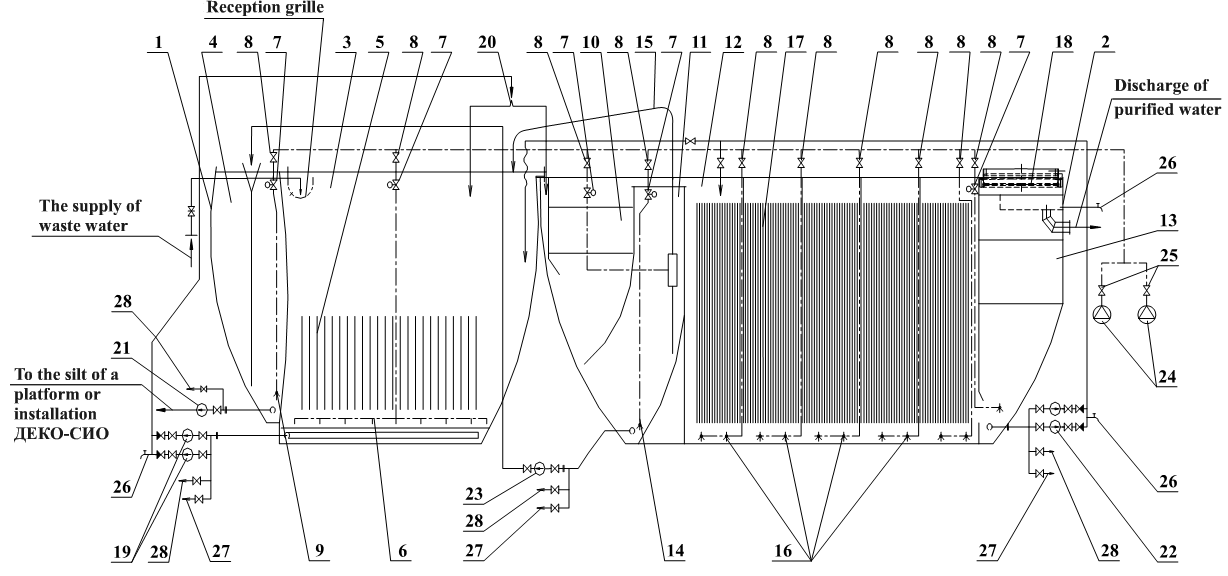

BIOLOGICAL TREATMENT PLANT ДЕКО-СВ

PRINCIPLE DIAGRAM

Explication

| 1. Body I; 2. Body II; | 15. Air-lift 16. Aerator; |

| 3. Equalizing preaeration tank; | 17. Bacteria bed; |

| 4. Аerobic stabilizer; | 18. Bactericidal disinfection unit; |

| 5. Bacteria bed; 6. Aerator; 7. Electromagnetic valve; 8. Shut-off valve; | 19. Wastewater transfer pump; 20. Flow distributor; 21. Stabilized sludge pump; 22. Pump; |

| 9. Aerator; | 23. Pump; |

| 10. Thin-layer primary desilter; | 24. Blowers; |

| 11. Storage hopper 12. Аerotank; | 25. Check valve; 26. Sampler; |

| 13. Thin-layer secondary desilter; 14. Aerator; | 27. Flush pipe.

|

Biological treatment plant ДЕКО-СВ operates in continuous automatic mode.

The work of biological treatment plant ДЕКО-СВ is carried out as follows:

Out-of-door sewerage pump station pump waste water through the intake screen into equalizing preaeration tank 3, 6-8 times a day at a volume, excluding the overflow from equalizing preaeration tank 3 into primary thin-layer desilter 10.

At this engineering solution equalizing preaeration tank 3, except its basic functional purpose - flow balance and pollution load balance in the incoming sewage, simultaneously function as preaerator. Aerator 6 is located at a bottom side of equalizing preaeration tank 3.

Pump 19 conveys sewage from equalizing preaeration tank 3 into primary thin-layer desilter 10 round-the-clock with the constant productivity, regulated by change of the redundant flow to recycling in the delivery pipeline by regulatory trays of the flow distributor 20. At the discharging of theequalizing preaeration tank 3 up to minimal level, wastewater transfer pump 19 is automatically switched off, and at filling ¾ switched on.

Sewage pass through the primary thin-layer desilter 10. Thus they pass a section of raw sludge which settles and arrives into the storage hopper 11 where, as a result of aeration, it is partially stabilised and mineralize. Air-lif in the storage hopper 11 of primary thin-layer desilter 10 (its aerobic part), is used for intensive formation of microflora in equalizing preaeration tank and its operating mode is established in the course of starting-up and adjustment works.

Аэратор 14, located in the bottom part of the storage hopper 11, provides accumulation without rotting илового a deposit during time of a running cycle of the aerobic stabilizer 4 for the account of course of the biological processes peculiar for aerated bunkers-stores.

Further sewage arrive in aerotenk 12 divided by partitions on seven sections in which bacteria bed 17 (screens) occupied by microorganisms are established. In the bottom part of aerotank 12 are mounted aerators 16 for air supply, providing in sewage necessary for maintenance of ability to live of microorganisms settlement quantity of the dissolved oxygen.

From aerotank 12 sewage arrive in secondary thin-layer desilter 13 where there is a section of sludge from biologically cleared sewage, and then on caps where lamps of the block of bactericidal disinfecting 18 with not shipped sources УФО carry out bactericidal processing of the cleared water by rigid ultra-violet radiation. The pathogenic microflora is as a result destroyed. The block design allows to regulate time of an irradiation of water and provides intensity of a stream of the radiation influencing water, not less than 28 mW-с/sm2. Optimum time of an irradiation of water is established in the course of starting-up and adjustment works.

Superfluous иловый the deposit detained secondary thin-layer desilter 13, collects in the bottom part of the bunker, whence periodically the pump 22 откачки silt pumps over it in equalizing preaeration tank 3. Duration and periodicity of work of the pump silt 22 is established in the course of starting-up and adjustment works.

After the block of bactericidal disinfecting 18 cleared and disinfected waters самотёком arrive in the first section of the block of deep additional cleaning with zeolitic loading. Then through overflowbranch pipes arrive in the second сорбционную a step of the block of deep additional cleaning with loading by active coal then the cleared waters are poured in reception capacity, whence periodically, in process of accumulation, are pumped out by the pump in waste a collector.

Raw sludge besieged primary thin-layer desilter 10, collects in the aerated bunker-store 11. Electromagnetic valves 7, established on аэраторах 14 and 9, the bunker-store 11 and the aerobic stabilizer 4, disconnect at 4-5 o'clock air giving. During this time there is a consolidation stabilised sludge in the aerobic stabilizer 4 and the storage hopper 11. Then the pump 21 pump silt for some minutes (time is established at starting-up and adjustment works) joins.

After pumping of condensed sludge from the aerobic stabilizer 4 pump 21 is switched off. The stop of the pump 21 is an impulse for inclusion of the pump 23 which pumps over condensed sludge from the aerated storage hopper 11 in the aerobic stabilizer 4. The Operating time of the pump 23 is established at starting-up and adjustment works. After that open the valve electromagnetic 7 and air giving in aerator 14 bunkers-stores 11 renews. Air giving in аэратор 9 stabilizers 4 renews with a delay at 1 o'clock. For this time clarified water passes through apertures in a partition in equalizing preaeration tank 3. The described cycle repeats automatically each 5-7 days. Readout of time for the next 5-7 days of a cycle of removal of sludge begins with the moment of the termination of work of the pump 23.

Air giving in aerators 6, 9, 14, 16 on air collectors is carried out from blowers 24.

Mode setting of nitrification and denitrification on sections of aerotank is carried out at starting-up and adjustment works.

Shipment of bodies ДЕКО-СВ-30 by rail. Assembled sewage treatment plant ДЕКО-СВ-30.

Designation when order (example):

"Sewage treatment plant ДЕКО-СВ-30, ТУ 4859-019-10442696-2009"

Photo gallery

Ecological certificate

Certificate of conformance

Теl./fax: (4832) 56-59-38

(4832) 52-19-33

(4832) 57-76-04

Company "ДЕКО", Brjansk

Wastewater treatment

and gas emissions

- Eng

- Rus